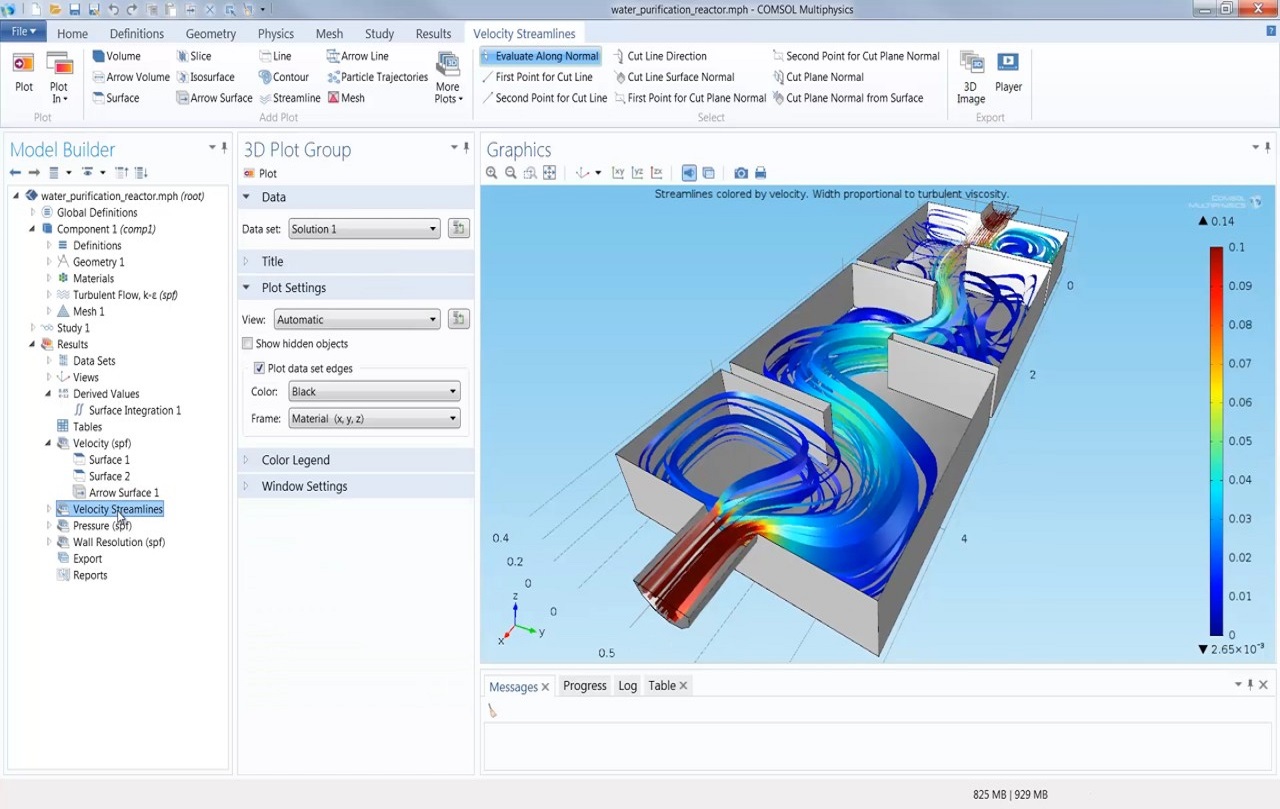

Single Phase Flow

FE Solve is an industry leader in applying Computational Fluid Dynamics (CFD) techniques to the design of equipments. We have executed number of projects for CFD based reports validating product safety or illustrating shortcomings. We perform single phase and multiphase simulation to understand behavior of fluid in different conditions also we check pressure, velocity, temperature of fluid throughput transportation.We specialized in:

- gas-liquid transportation

- crude oil recovery

- circulating fluidized beds

- sediment transport in rivers

- pollutant transport in the atmosphere, cloud formation,

- fuel injection in engines

- bubble column reactors

- spray driers for food processing

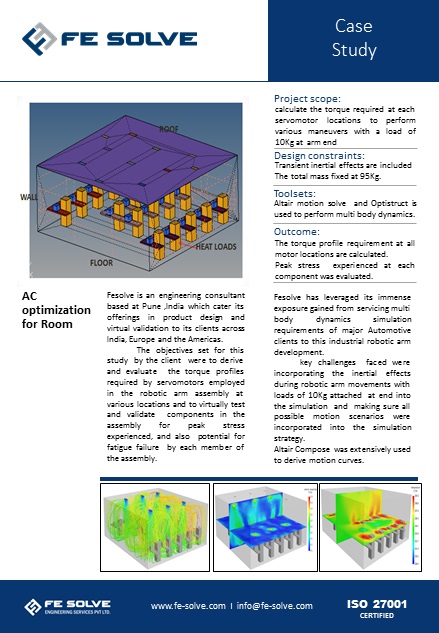

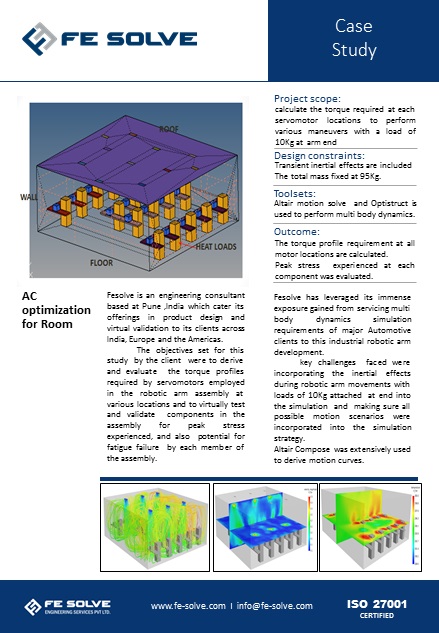

AC optimization for Room

Download Now

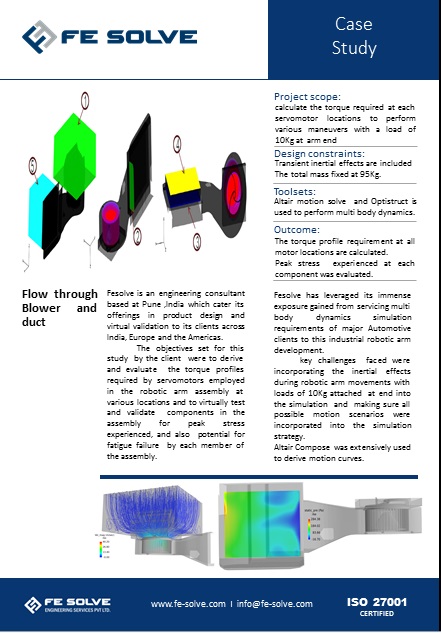

Flow through blower evaporator ducting

Download NowFlow inside Refrigerator Cabin

Download Now

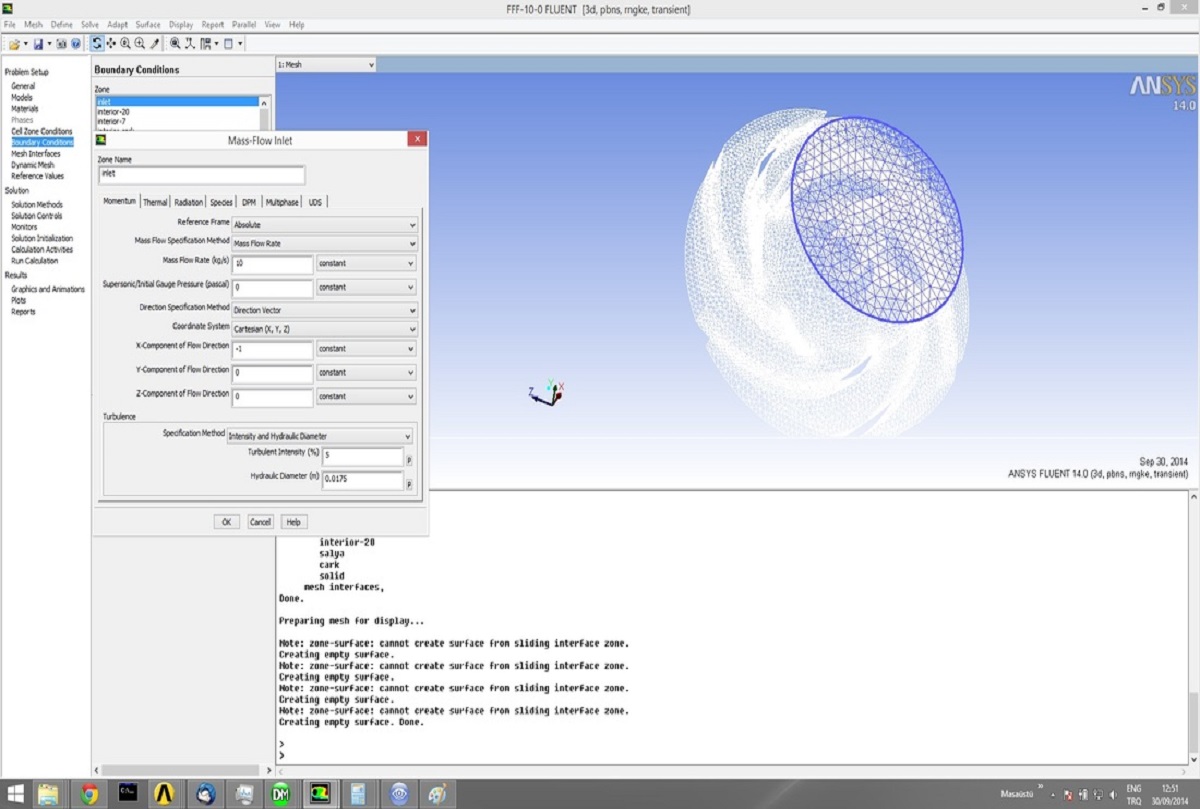

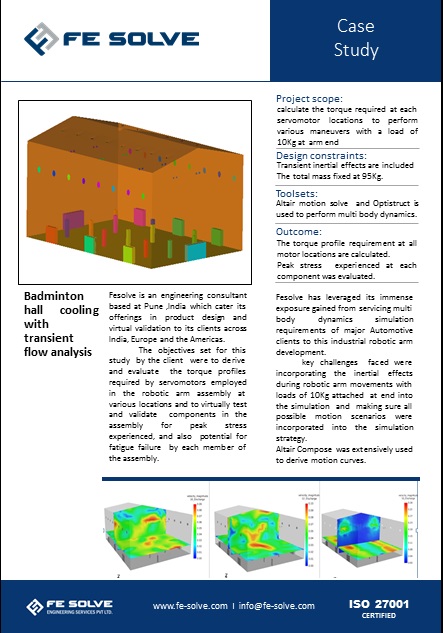

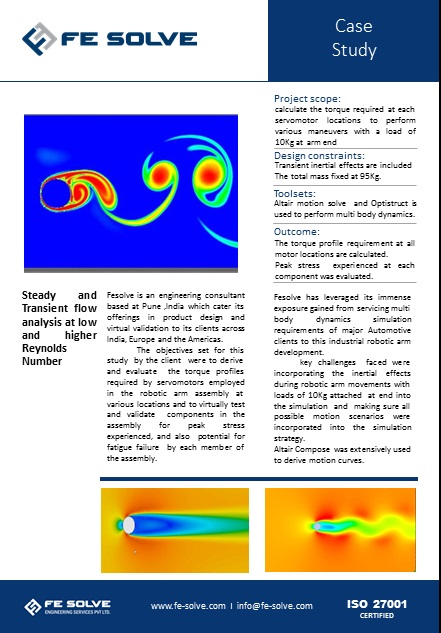

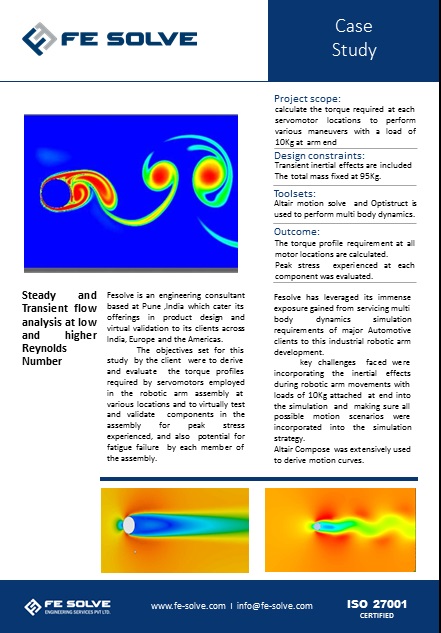

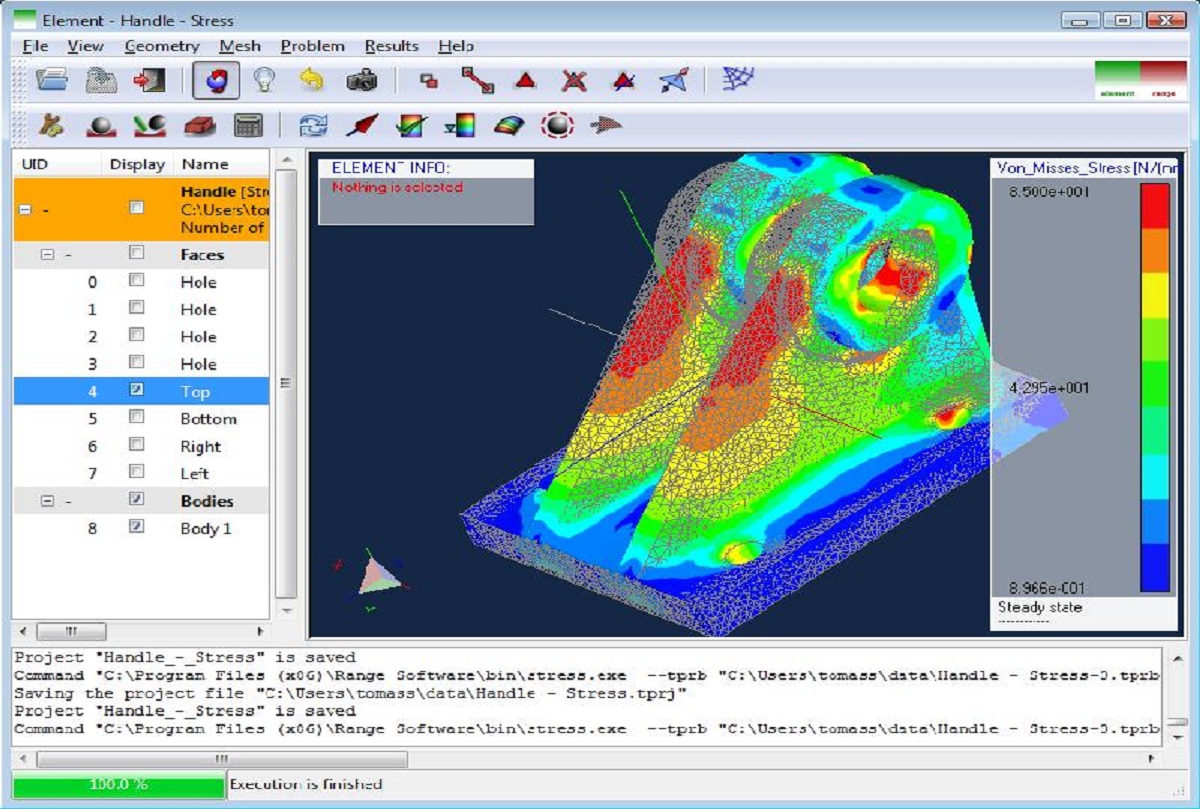

Steady State

FE Solve experts in time dependence flow characteristics simulation which can be specified as either steady-state or transient. We apply steady state characteristics on fluid for which behavior do not change with time and whose steady conditions are assumed to have been reached after a relatively long time interval. Transient simulations require real time information to determine the time intervals at which the solver calculates the flow field. They therefore require no real time information to describe them. We specialized in:

- Flow through pipe under constant head

- Pump flow analysis

- Fan and blower analysis

- Flood wave analysis

- Irrigation and power canal analysis

- Tidal effect

- Junctions flow analysis

Badminton hall cooling Transient flow Analysis

Download Now

Flow at Steady Transient state

Download Now

Chimney Transient flow Simulation

Download Now.jpg)

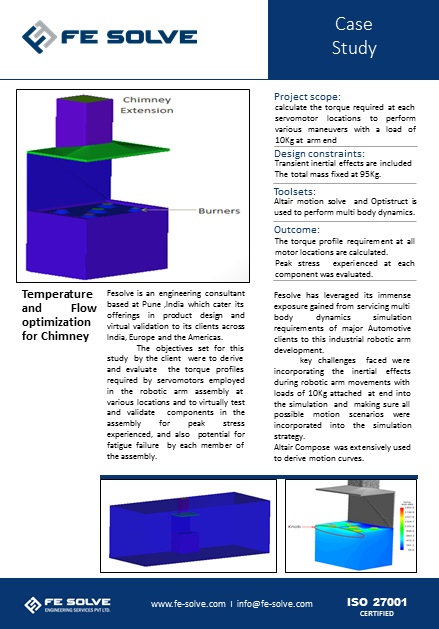

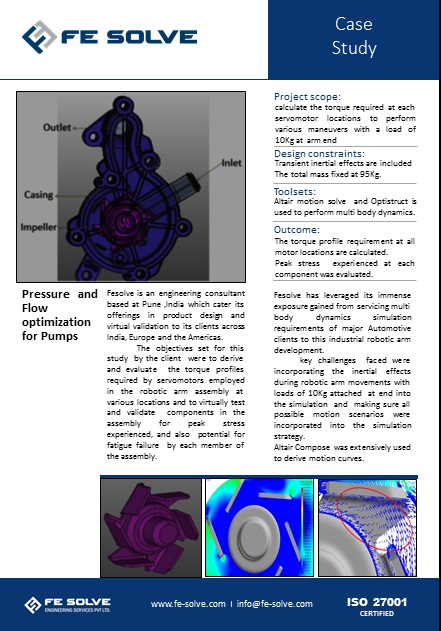

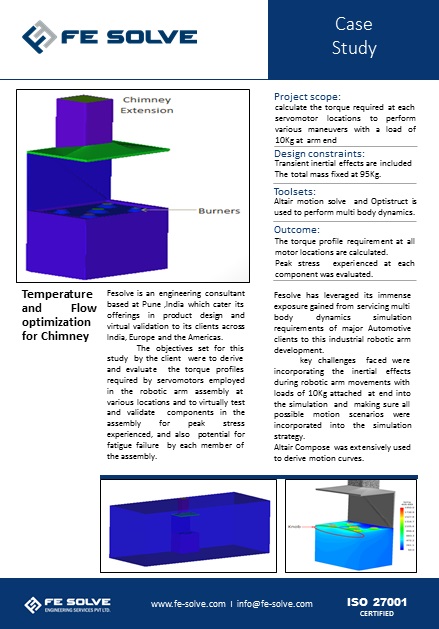

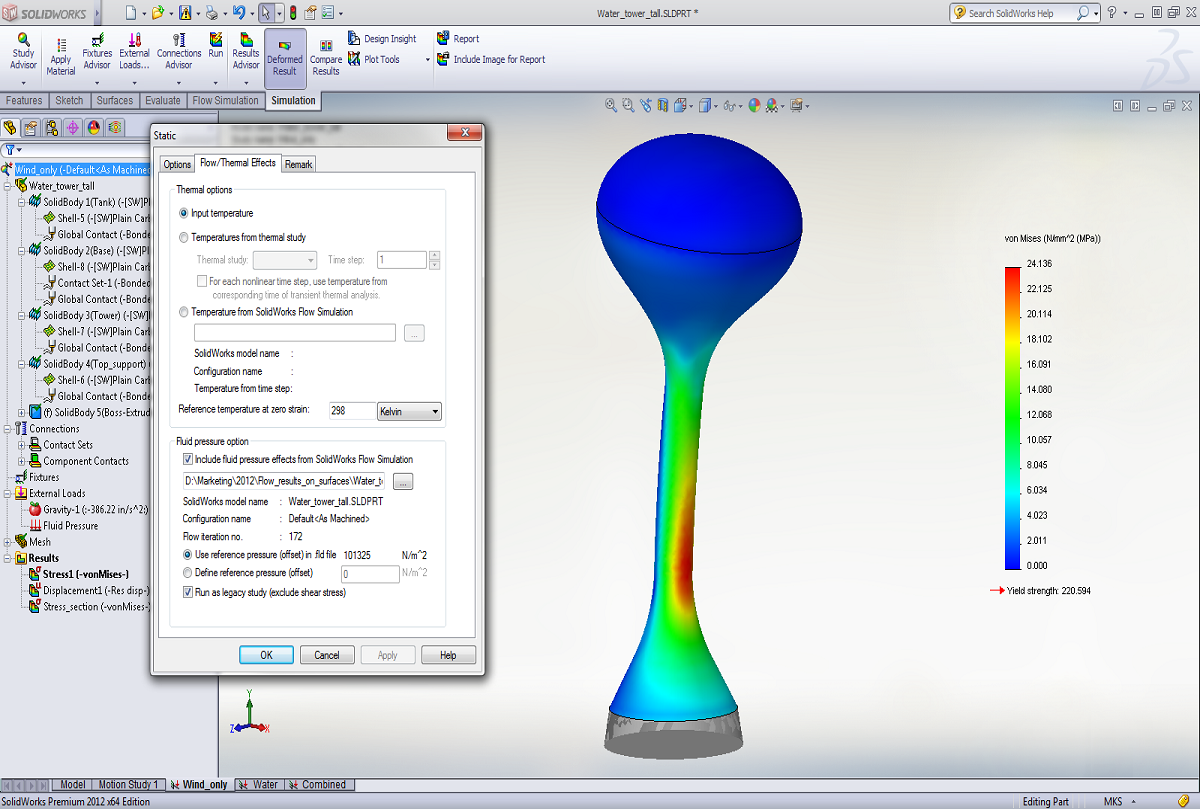

Temperature and Pressure flow analysis

FE Solve's core CFD team manage to check performance of system. We are specialized into mapping exact temperature and pressure onto components by considering all exact parameters.We are specialized into:

- Flow through pipe

- Pump

- Exhaust System

- Cyclone and Dam break analysis

- Fuel injection in engines

- Underhood cooling

- Aerodynamic Analysis

- Turbo machinery

- Tidal Effect

- Flood wave Analysis

Pressure and flow optimization for pumps

Download Now

Temperature and flow optimization for chimney

Download Now

Temperature and Flow analysis inside office room

Download Now.png)

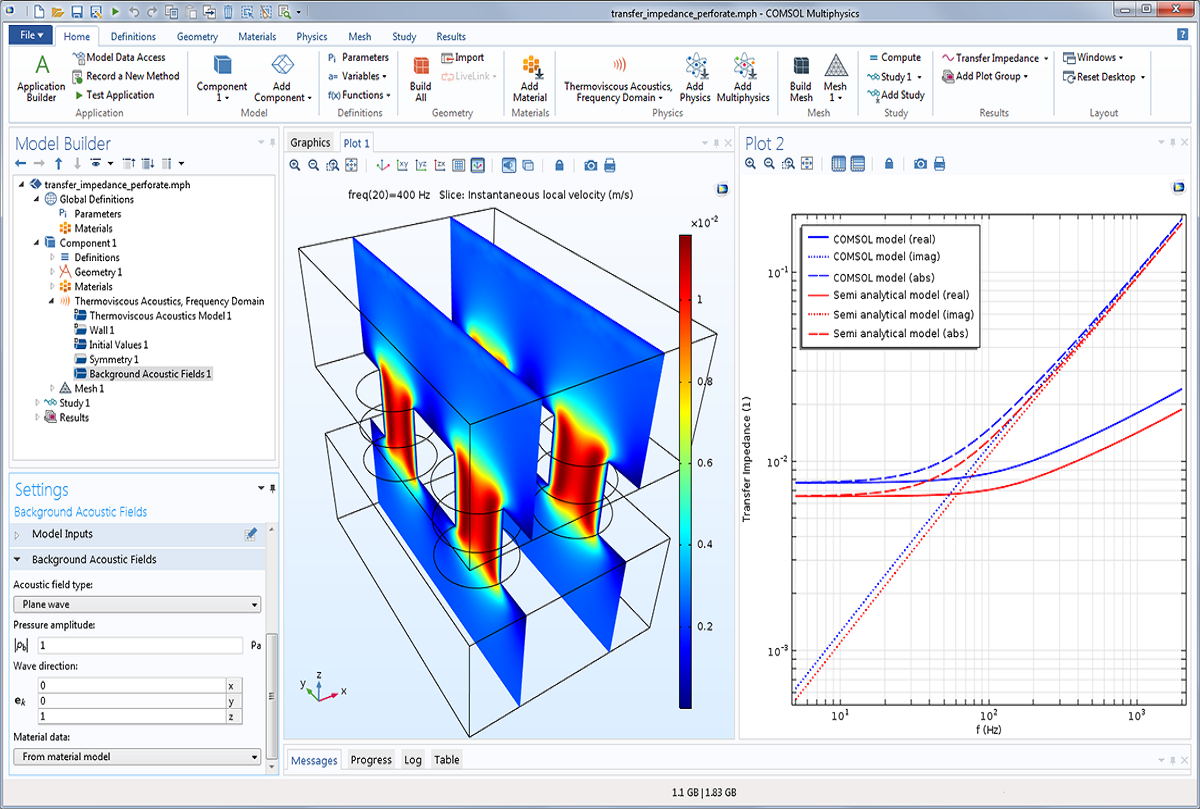

Compressible/ Incompressible flow analysis

FE Solve performs CFD simulation for fluid flows which are compressible or incompressible. Compressible flows are usually high speed flows with Mach numbers greater than about 0.3. This is important to note because analyses run as compressible require more longer analysis times than incompressible flows. We usually perform compressible flow analysis on:

Aerodynamic applications such as flow over a wing or aircraft nacelle as well as industrial applications such as flow through high-performance valves.

We perform incompressible flow analysis on:A fluid such as air that is moving slower than Mach 0.3 is considered Incompressible, even though it is a gas. A gas that is run through a compressor is not truly considered compressible (in the thermodynamic sense) unless its velocity exceeds Mach 0.3.

Flow analysis at Higher Mach number

Download NowFlow analysis for NACA at Mach above 1

Download NowIn compressible flow analysis for Pumps

Download Now.jpg)

.jpg)

Fluid Structure Interaction

We perform Fluid structure interaction on some movable or deformable structure with an internal or surrounding fluid flow. During this we perform Fluid–structure interactions on stable or oscillatory systems. We check for fluid flow which deforms a physical structure, which in turn changes the fluid flow. This two-way interaction loop continues through multiple cycles, possibly resulting in structural damage and less-than-optimal flow. We perform FSI on:

- Aircraft

- Spacecraft

- Engines

- Bridges

- Aircraft wing

- Turbines

- Valves

- Nozzles

- Containers

Flow analysis and Structural stability for Fluid Valves

Download NowFlow analysis and Structural Stability of Impeller

Download NowFlow analysis and Structural Stability for Windmill Blades

Download Now

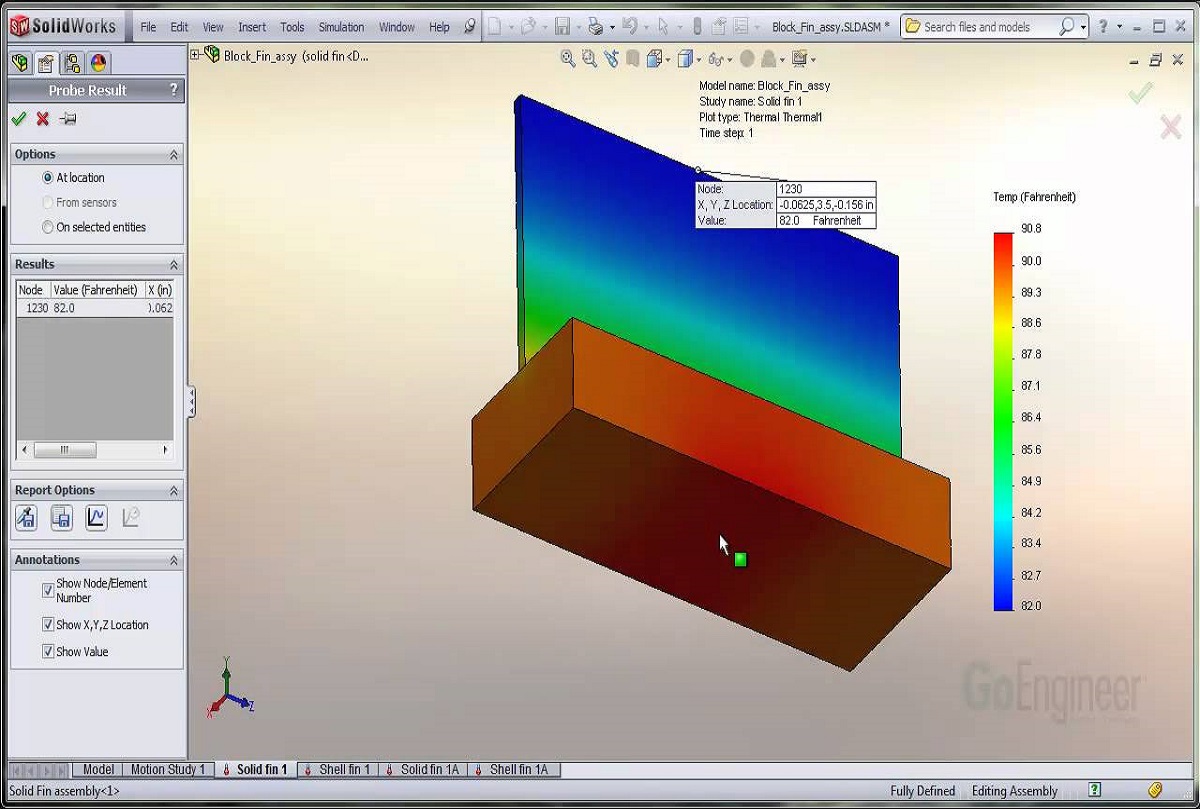

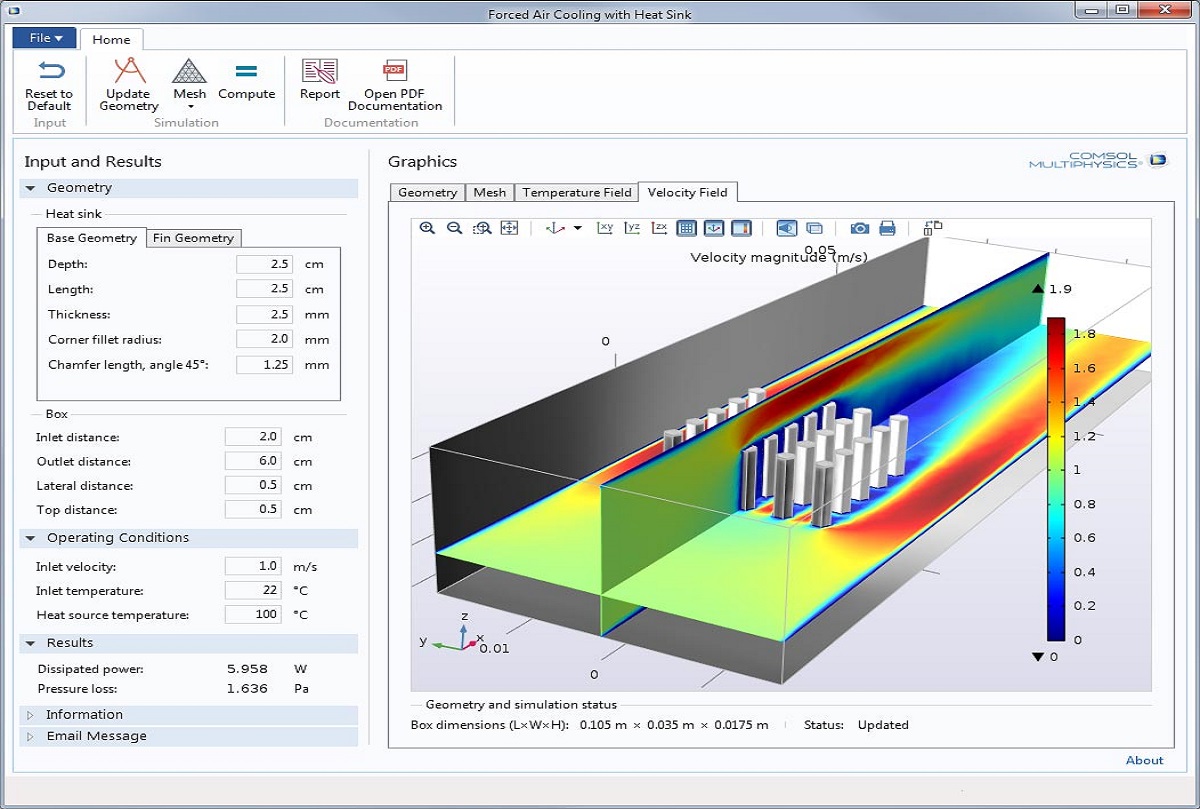

Conjugate Heat Transfer Analysis

At FE Solve we perform Conjugate heat transfer corresponds with the combination of heat transfer in solids and heat transfer in fluids. In solids, conduction often dominates whereas in fluids, convection usually dominates. We consider heat transfer between a body and a fluid flowing over or inside it as a result of the interaction of two objects. We perform CHT on:

- Aircraft

- Aerospace

- Nuclear Reactors

- Heat Sink

- Food processing

- Electronic cooling

- LED lighting

- HPC cooling

Conjugate Heat transfer analysis for Electronic component

Download NowConjugate Heat Transfer analysis inside Tube

Download Now

Flow through blower evaporator ducting

Download Now

.jpg)

Reacting flows and combustion Analysis

At FE Solve we perform reacting flow analysis which are highly turbulent. Similarly we perform combustion analysis which creates turbulence through a variety of mechanism including flow acceleration and modified kinematic viscosity. We perform reacting and combustion analysis on:

- Engines

- Chemical industries

- Medical industries

- Food industries

- Nuclear reactors

- Air pollution

Chemical Reaction and Combustion inside Manifold

Download NowCombustion and Cycle Simulation for 4 Strokes Engine

Download Now

Flow through blower evaporator ducting

Download Now.png)

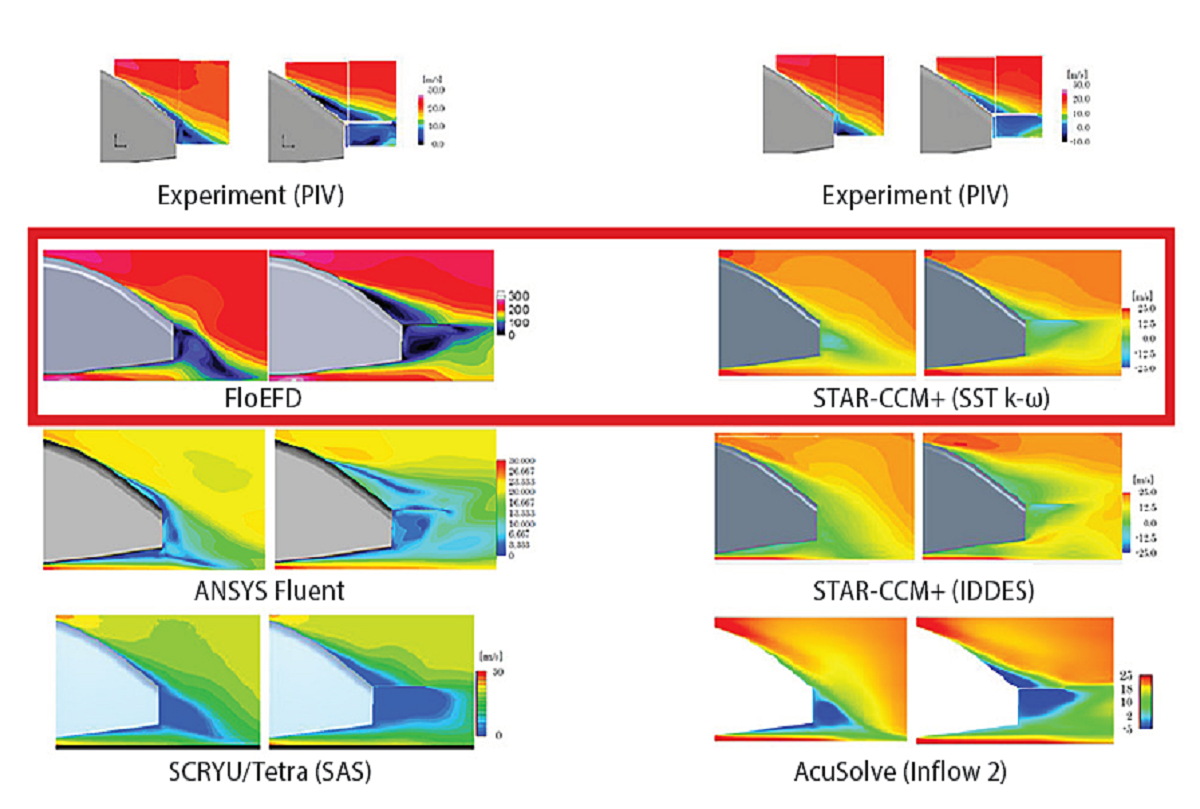

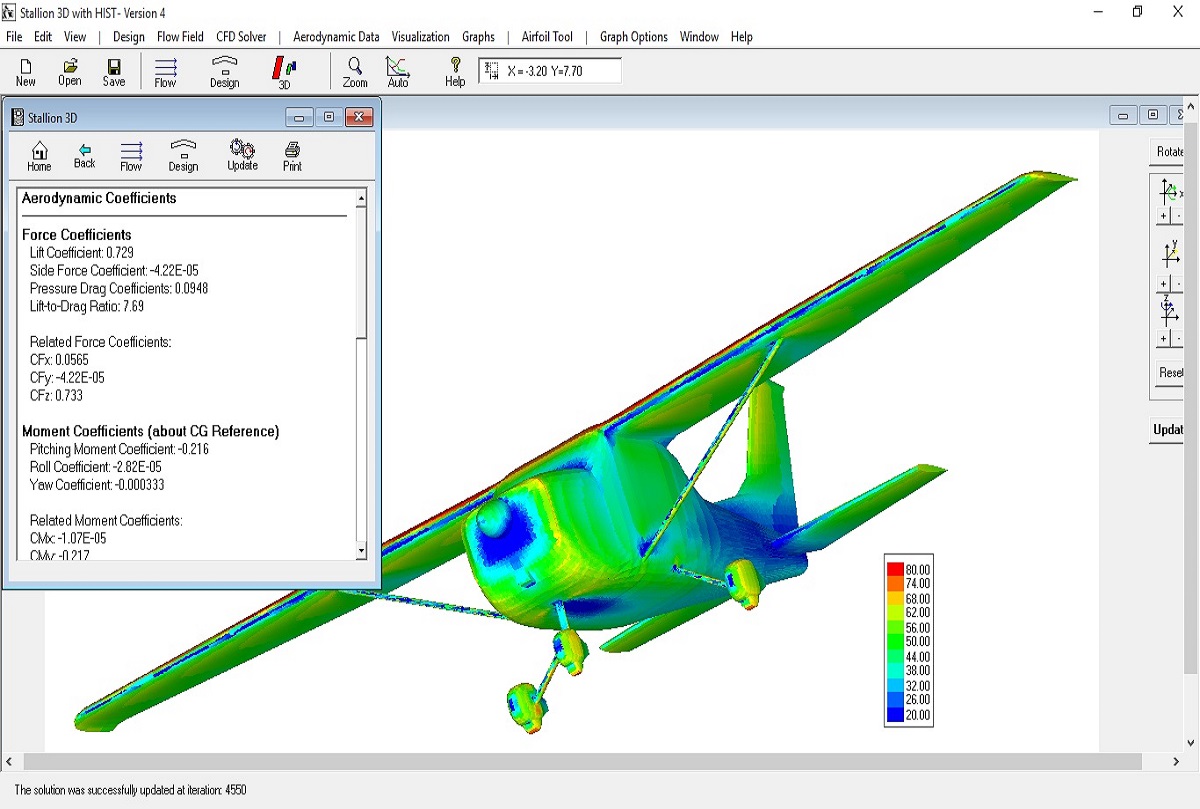

Aerodynamic Analysis

FE Solve offers aerodynamic analysis of various components. Our expertise in this field leads to efficient product performance with better useful drag and lift values. Aerodynamic morphing with design of experiment to achieve efficient design.

We perform aerodynamic analysis on:Automobiles for exterior body, interior air flow simulation, fan and rotor system,Aerospace, for aerodynamics of wings, fuse large, and body, optimization of cabin air flow patterns.

Turbo machinery components like turbines, compressors, and pumps to improve flow performance.Building structure for external wind loads.

Drag and Lift Analysis for Aerodynamic body

Download NowDrag and Lift calculation for F1 car model

Download Now

Flow through blower evaporator ducting

Download Now

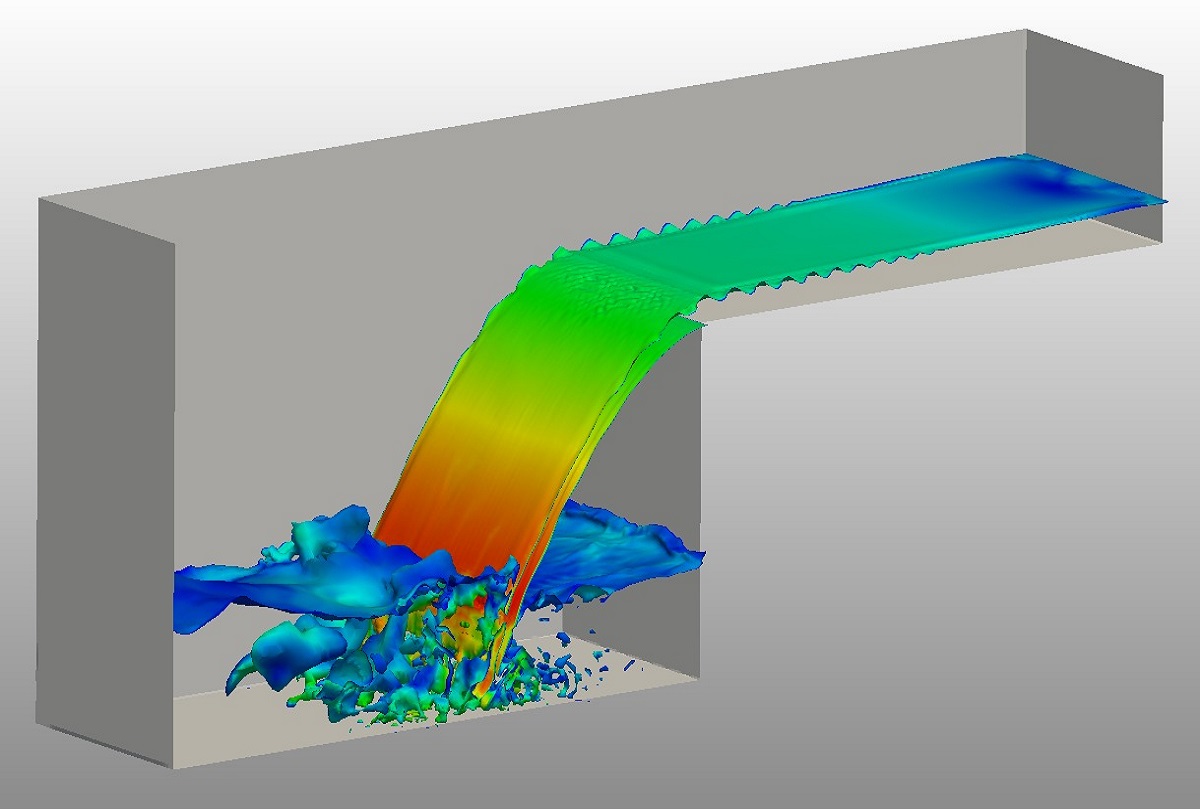

Multiphase Flow

Multiphase flow is simultaneous flow of materials with different states or phases (i.e. gas, liquid or solid), or materials with different chemical properties but in the same state or phase.

Flow mixing inside the container

Download Now

Multiphase Simulation

Download Now

Flow through blower evaporator ducting

Download Now

Cavitation Modeling

At FE Solve we perform cavitation modeling for pump, turbines models to achieve better performance of model. We work on vapor transport model also on discrete bubble model to investigate cavitation. Cavitation is important to investigate the behavior of fluid and also to increase life of component parts.

- Centrifugal Pumps

- Radial Pumps

- Turbines

- Compressors

- Turbo jets

- Pump inducers

- Fuel injection

Blower simulation for Cavitation and Turbulence intensity

Download NowFlow inside the pump for Cavitation and Turbulence Intensity

Download Now

Flow through blower evaporator ducting

Download Now

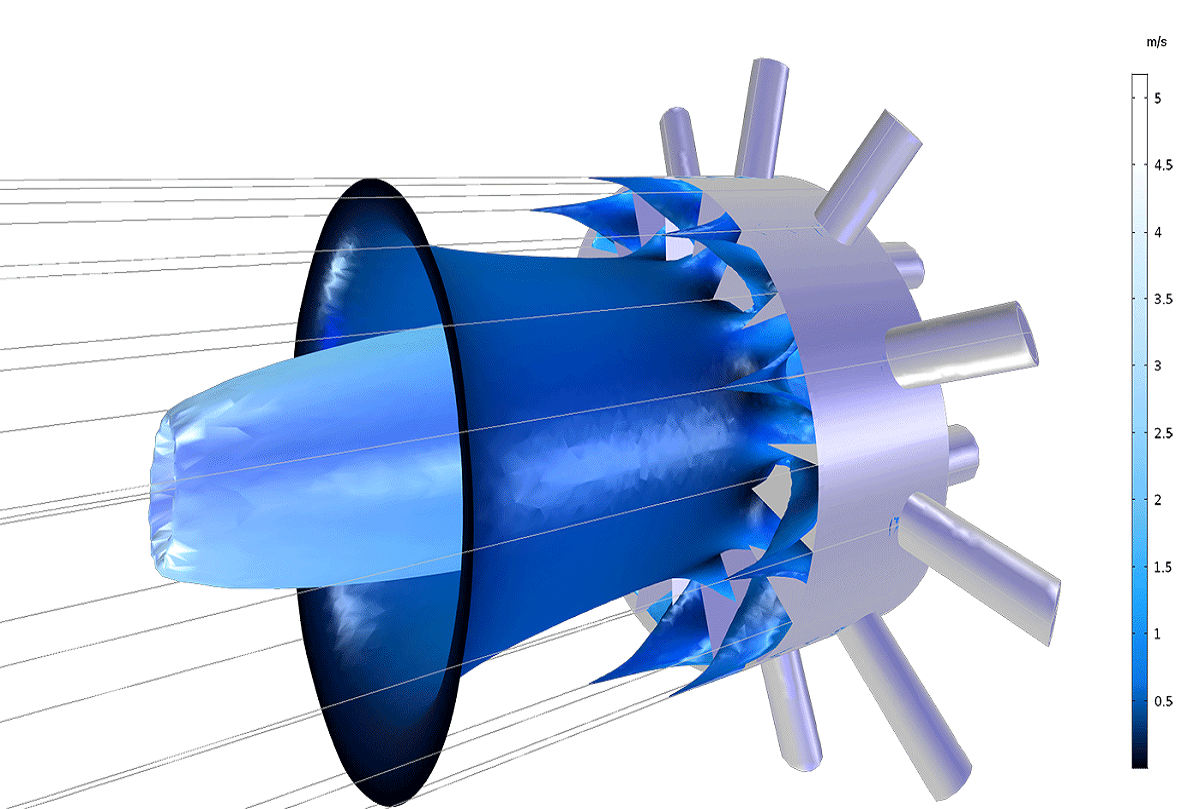

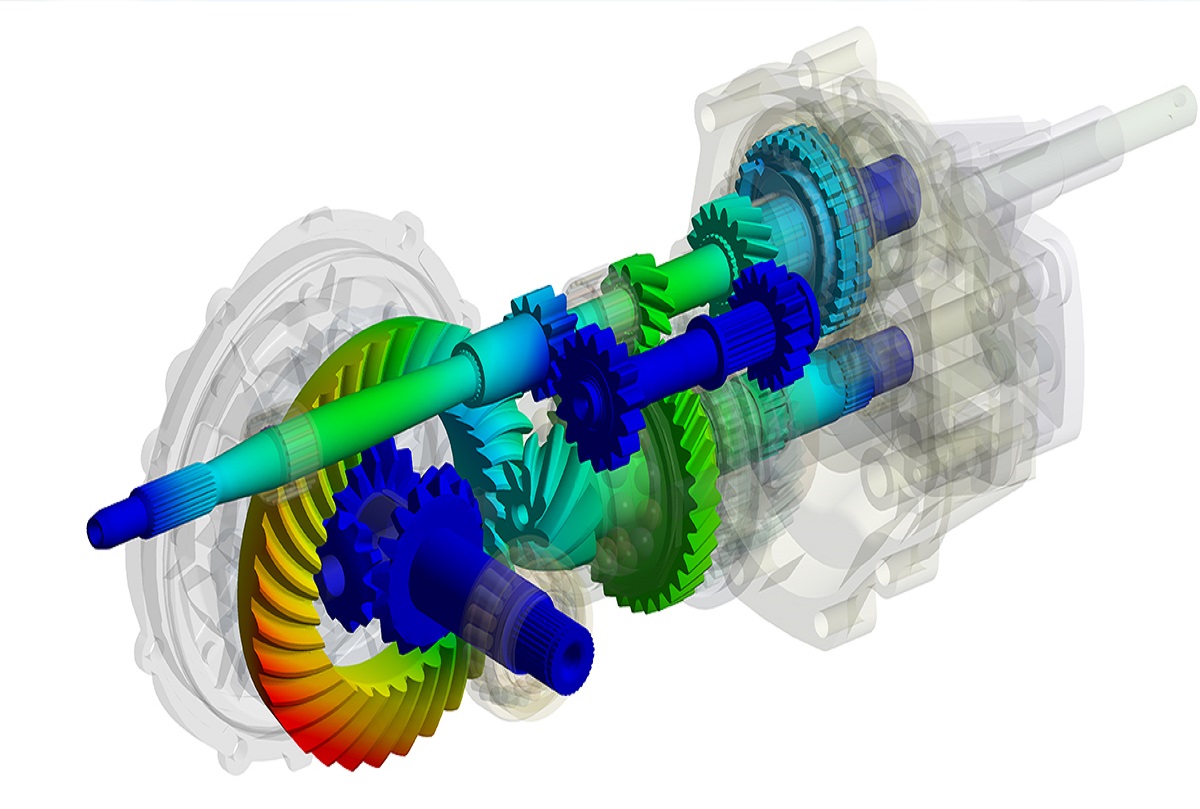

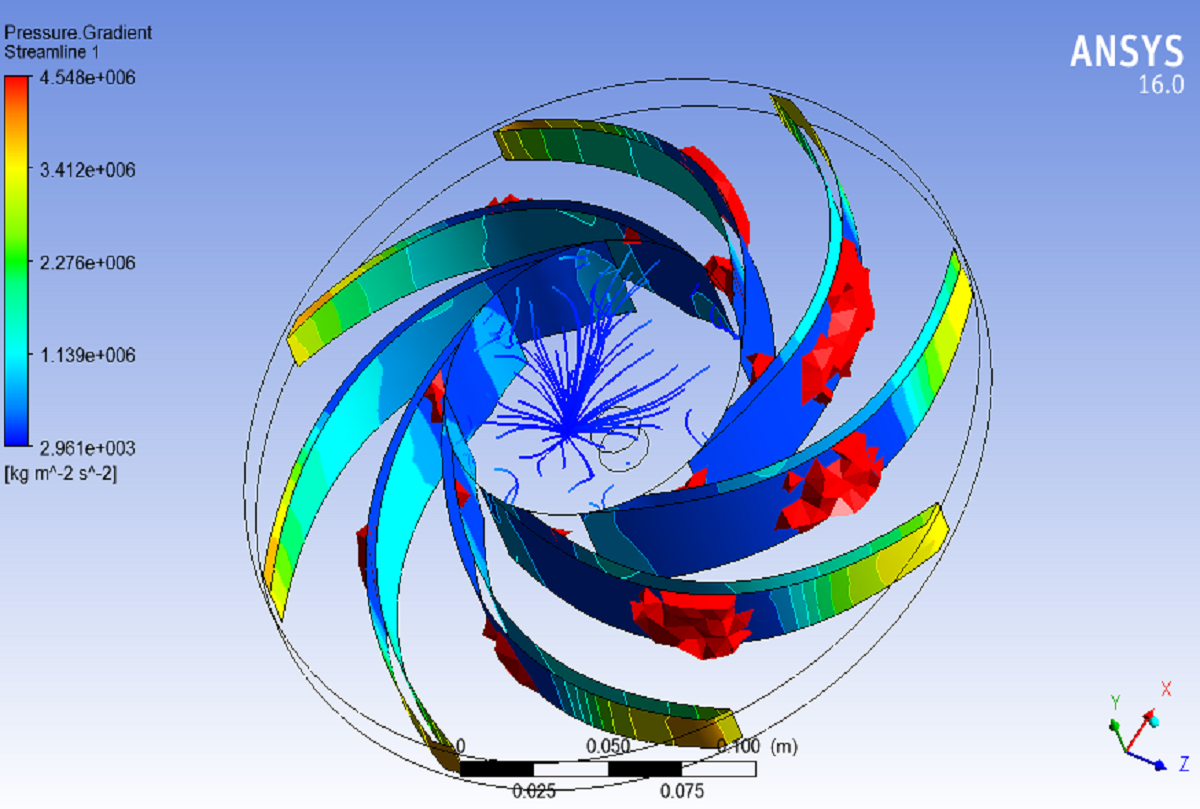

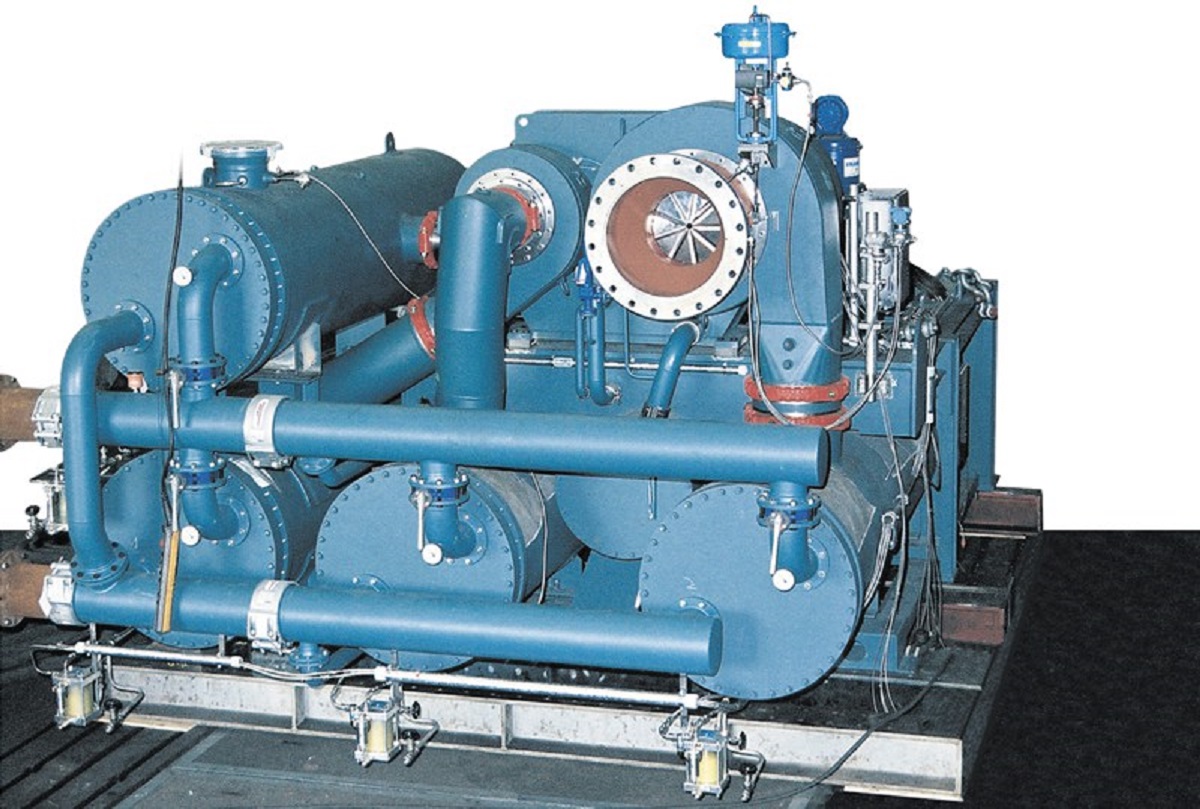

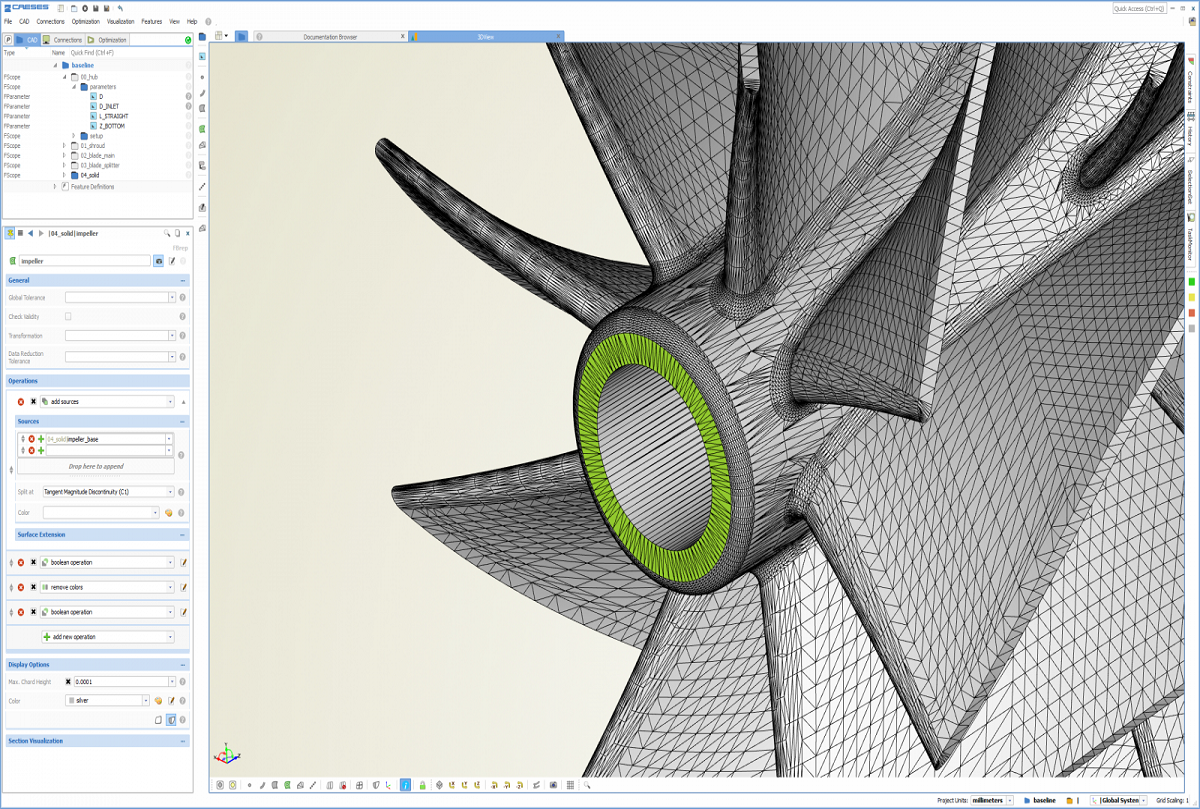

Turbo machinery Analysis

At FE Solve we optimize the design for turbomachinery to achieve maximum efficiency performance. With efficiency we also work on safety, pressure, velocity, thermal, to provide complete solution to the product. In industrial applications for turbomachinery small changes in efficiency will cost a huge impact on budget and also to time to market. Currently we are specialized into:

- Compressors

- Pumps

- Turbines

- Fans

- Blowers

- Turbochargers

- Turbo pumps

Centrifugal Pump flow analysis for Industrial application

Download NowCFD Simulation for Hydro power plant

Download Now

Flow through blower evaporator ducting

Download Now.png)