Meshing

From easy, automatic meshing to a highly crafted mesh FE Solve provides the ultimate solution. During meshing we maintain critical quality criteria suggested by customer. FE Solve has extensive experience in the meshing of sheet metal and plastic components. We perform all types of meshing support which includes :

- Tetrahedral meshing

- Hexahedral meshing

- Hybrid meshing

- Surface meshing

- beam meshing

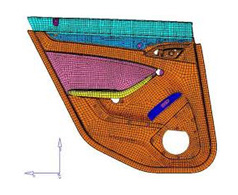

Automotive Interiors Meshing

Download Now

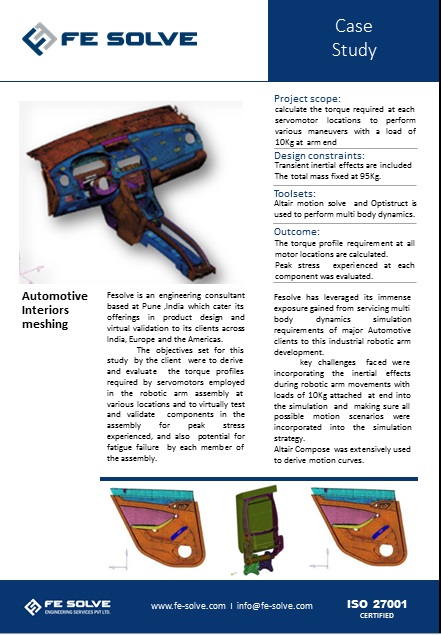

Full Vehicle Meshing

Download Now

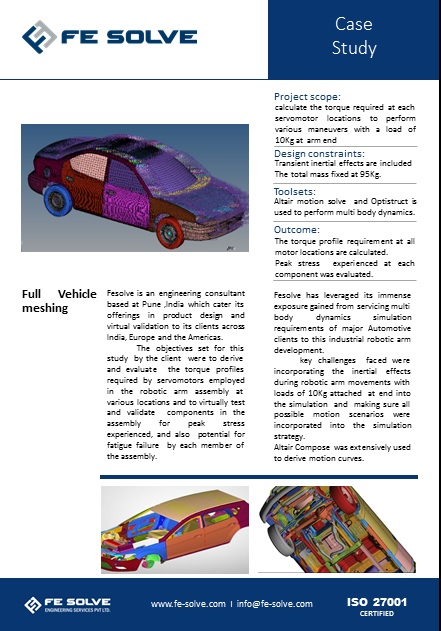

Multi-zone Meshing in Duct

Download Now

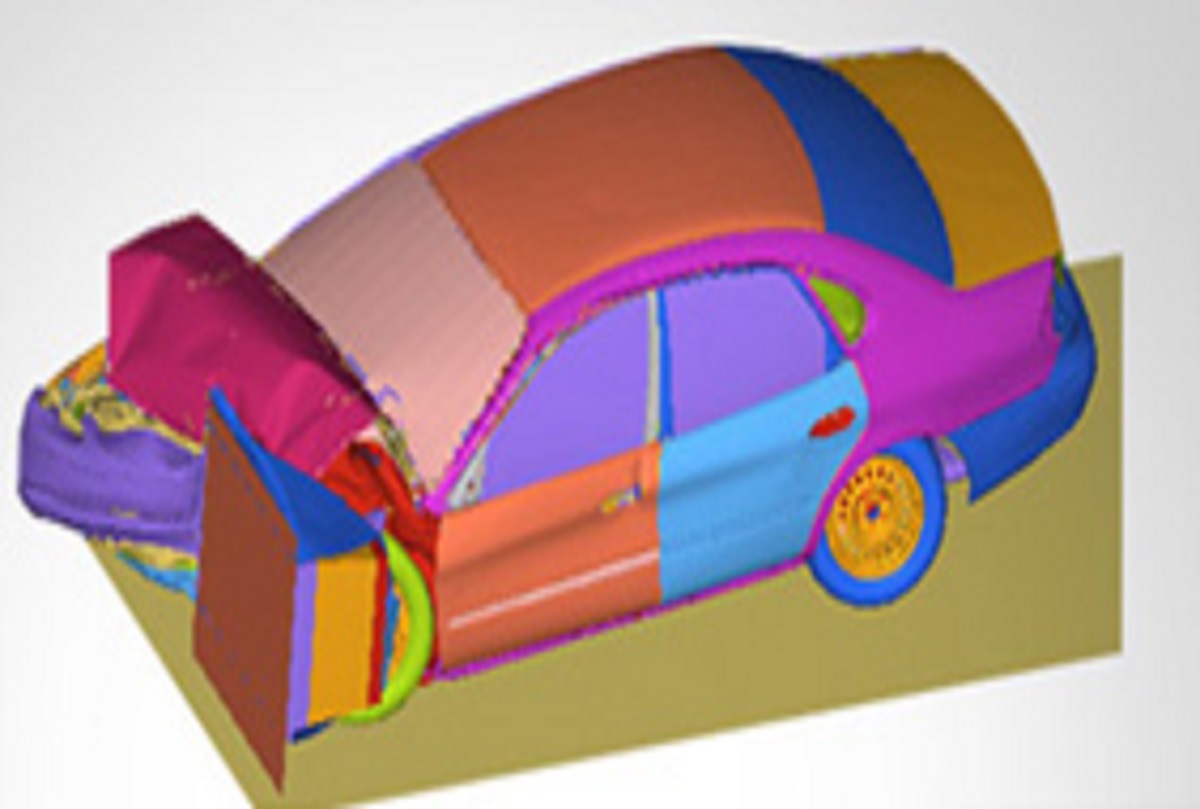

Impact, Crash and Safety Analysis

FE Solve assists OEMs and their suppliers with comprehensive CAE development services for crash behavior in complete vehicles. In doing so, it integrates local and safety guidelines and consumer tests such as the US and Euro NCAPs and takes them into account during the development process.Requirements include the following:

- Frontal impact: high and low speed

- Side impact: dynamic and quasi static

- Rear impact: high and low speed

- Simulation of crashes under objects

- Roof crush test

When a comparison is required between test and simulation findings, FE Solve focuses on mapping the actual test conditions. Thanks to our expertise, we are able to achieve the best possible results during validation. In this way, we are able to reduce correlations to a necessary minimum.

CAE delivers its greatest benefit at early stages in product development. Starting from the pre-development and conceptual design stages, we offer reliable calculations and analyses which advance development in the right direction.

Automotive crash and impact analysis

Download NowDrop Test for Microwave Oven packaging

Download NowAutomotive crash and impact analysis

Download Now

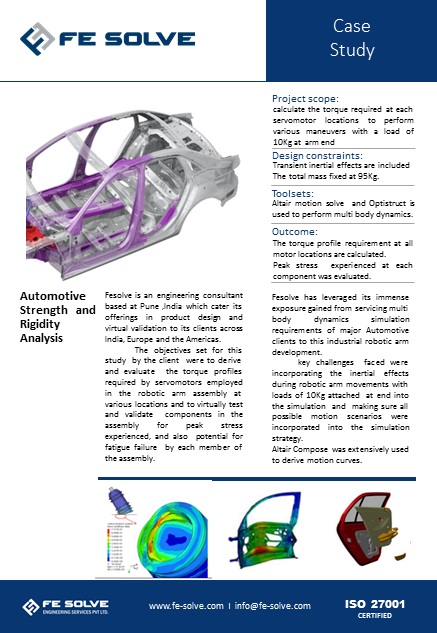

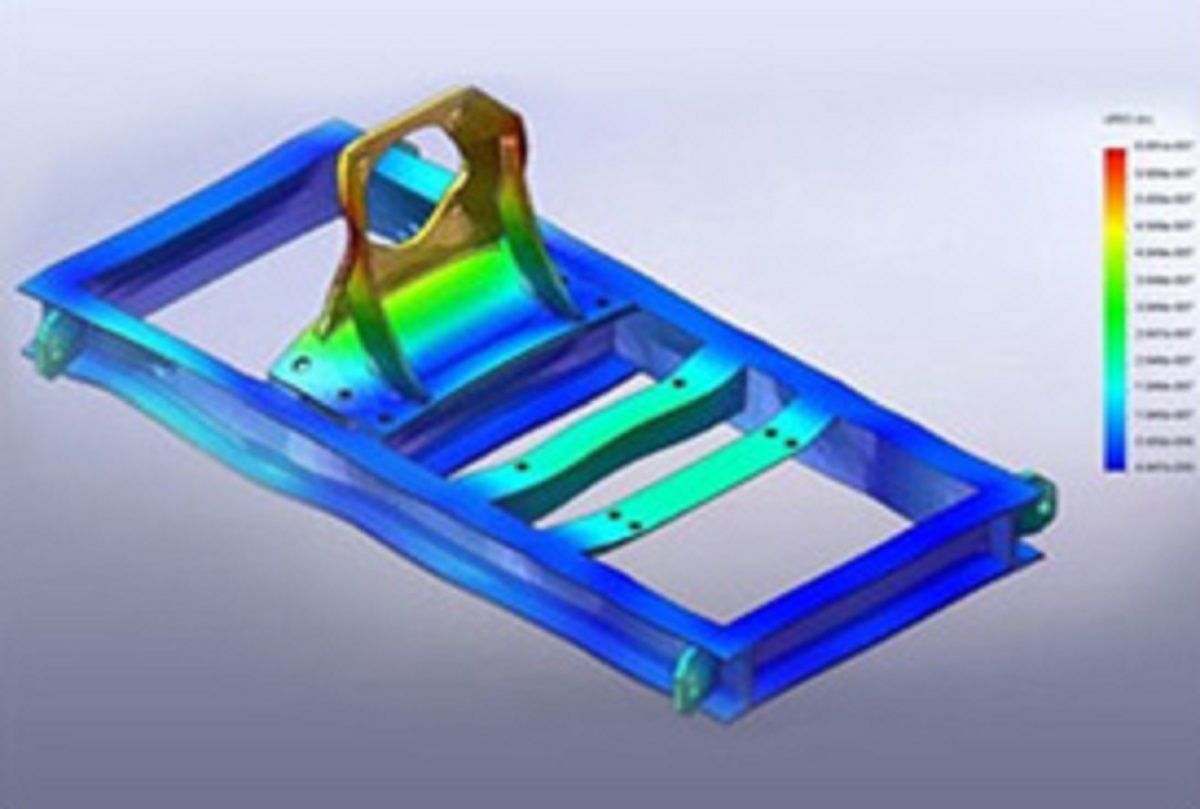

Strength and Rigidity Analysis

At FE Solve we examine the tightness of structures and assess precisely what geometry would result in ideal stiffness for a particular product and also explain the sorts of are proper and quite helpful for the product involved.Different factors are considered when setting up the perfect stiffness values: on the one hand, most products need to contain versatility to a particular limit as challenges and vibrations take place when products are consumed.Once products were inflexible, these forces and vibration may cause problems. However, if perhaps a structure attributes inadequate tightness, the structure might collapse a whole lot that the product can never be utilized successfully.We conduct extensive tests of static and vibrant stiffness :

- Static bending / tensile durability

- Static torsion / torsional stiffness

- Local static stiffness

- Stress analysis

- Local dynamic stiffness

We build alternatives for an enhanced geometric design of structures depending on the discovery from such tests. This growth procedure additionally concentrates on light-weight design, as the goal is to attain ideal stiffness with the minimum weight possible. Strength AnalysisThe strength analysis for cyclic loads, basically, operating loads, relies upon operational resistance measurement or fracture mechanics calculation, based on the purpose of the evaluation. An operational stability calculation ascertains, primarily, service life until harm is experienced. Conversely, linear fracture technicians calculations are widely used to figure out the further advancement of damage along with the remaining service life of a component.

Automotive strength and rigidity analysis

Download NowStrength and Bending Analysis for Cantilever Beam

Download Now

Automotive strength and rigidity analysis

Download Now

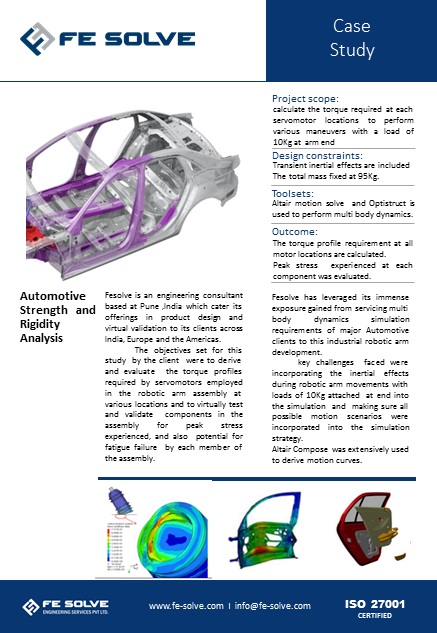

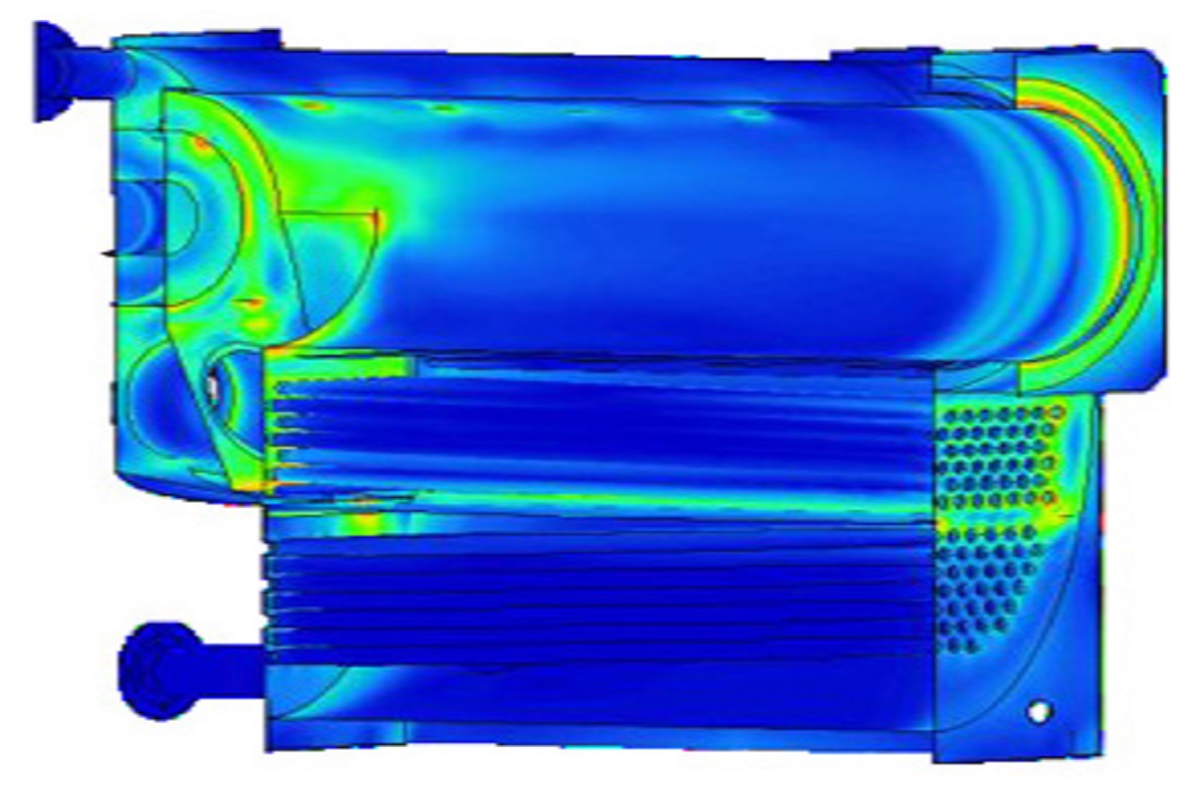

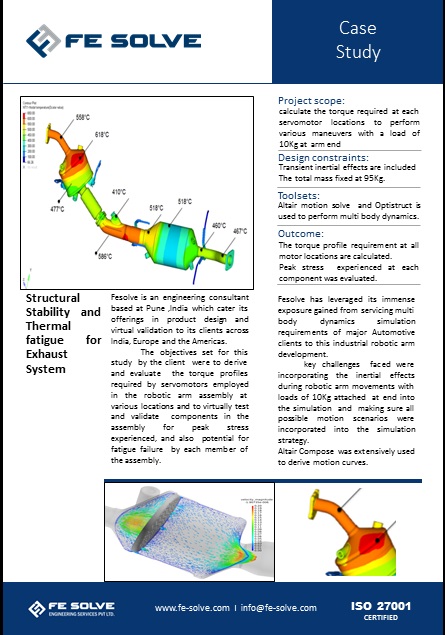

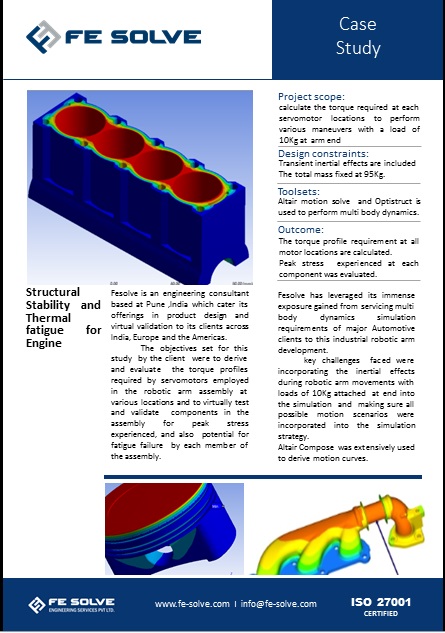

Thermal Analysis

FE Solve expertise in thermal analysis and thermal fatigue of various components and assembly. Our thermal analysis services include cooling for electronic enclosures, heat exchangers, electric motors, furnaces, and gas turbine engine components. We are experts in providing cost-effective solution for design and optimization of electronic cooling systems.

- Transient Analysis

- Radiation Analysis

- Heat Transfer Analysis

- Steady State Analysis

- Thermo-Mechanical Analysis

- Creep Analysis

- Conduction Analysis

Structural stability and thermal fatigue for engine

Download Now

Structural stability and thermal fatigue for Exhaust System

Download Now

Structural stability and thermal fatigue for engine

Download Now

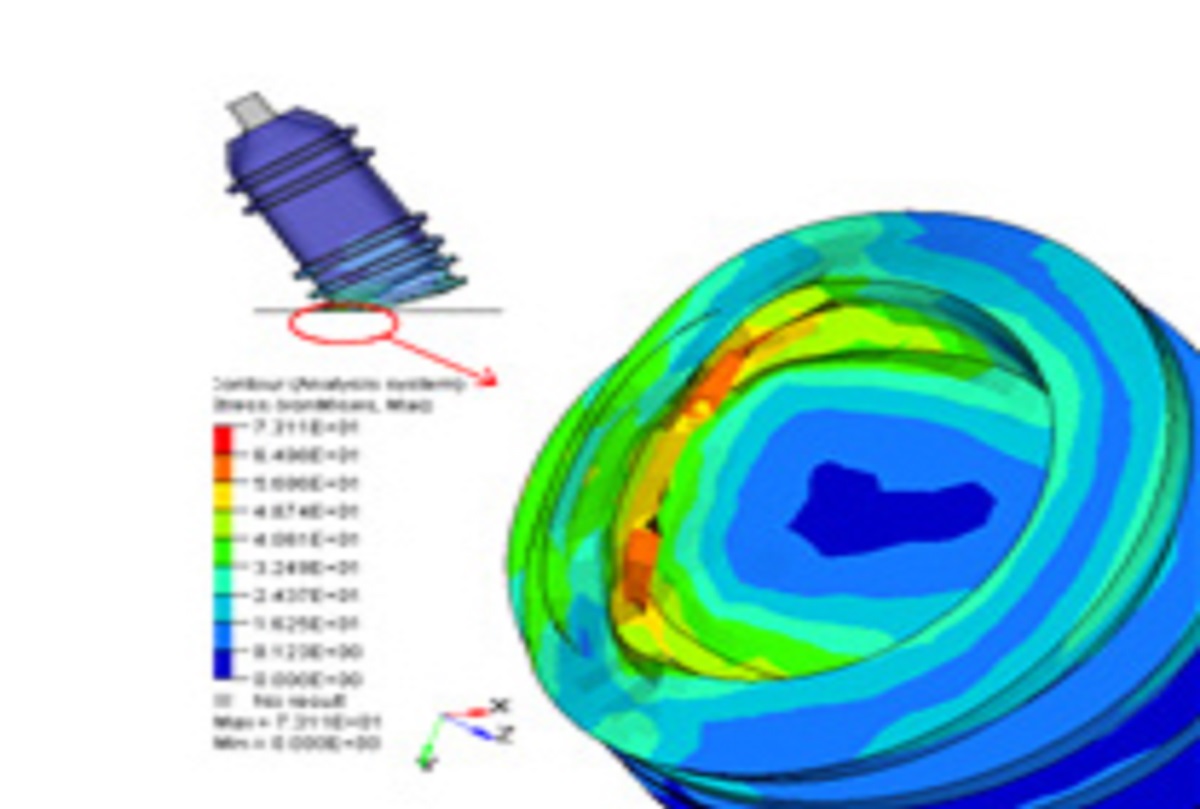

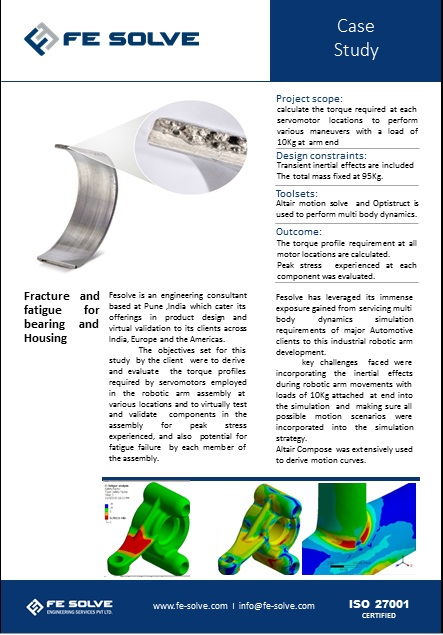

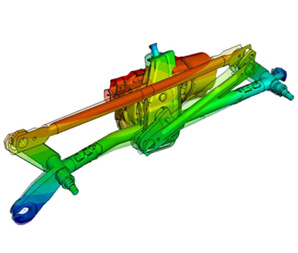

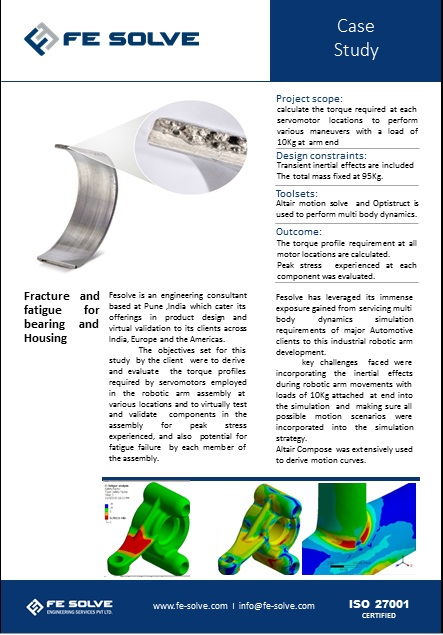

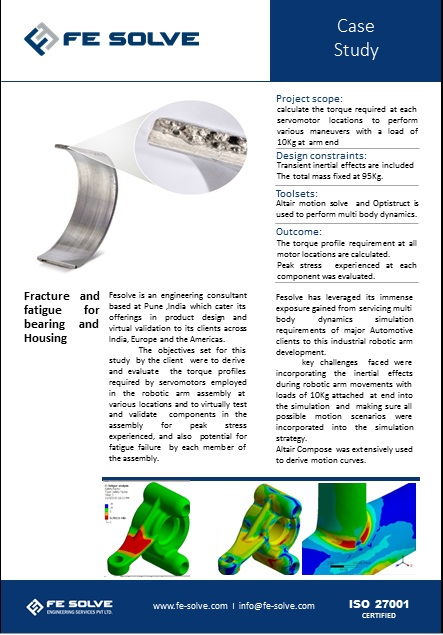

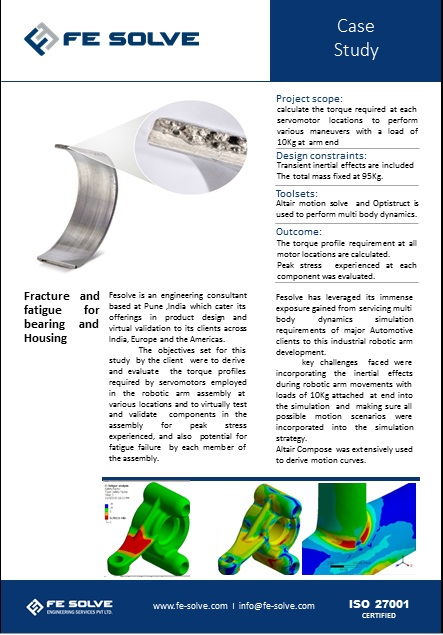

Fracture and Fatigue Analysis

Through fatigue analysis our expert FEA engineering consultants can determine the durability of components constructed from just about any material, including: metals, plastics, alloys, composites, rubber, glass, concrete, synthetic materials, and more. We do this under various combinations of conditions including static, dynamic, and thermal loading.We'll help you understand everything you need to know about your design with respect to its durability, fatigue, and fracture tolerances, including the cause of failures, margin of safety, recommended design changes for improvement, recommended inspection intervals, and more.

Fracture & Fatigue For Bearing and Housing

Download NowFracture Growth Analysis near Bending surface

Download NowStress and Fatigue for Hinges during dynamic movement

Download Now

NVH Analysis

FE Solve specialized in detecting the dynamic structural properties and utilize extensive NVH analyses to optimize all of them.Our technicians perform damped and un-damped vibration evaluation on various vibration techniques to ascertain dynamic structural properties. Energetic habits can indeed be analyzed, envisioned and enhanced depending on natural frequencies and organic reactions in a period and over a particular frequency span.For the vehicle industry, we have specialized on the following calculations in the area of dynamics :

General natural frequencies :

- Torsion

- Vertical bending

- Lateral Bending

- Front-end bending

- Rear parallelogram

- MAC factors

Modal analysis, local ( examples ) :

- Steering column

- Replacement wheel recess

- Doors, hatches, attached parts

- Roof cross associates

- Module cross associates

- MAC factors

Frequency reaction analysis

( examples ) :

- Frequency reactions to ease points

- Operational vibration methods

- Modal participation factors

- Local dynamic stiffness ( LDS )s

- Design of vibration absorbers

- Mirror shake

- Steering wheel shake

- Gear shift vibrations

We are also primarily focused on NVH for vehicle industry applications :

NVH for Engines

Download NowNVH for Radiator Fan

Download Now

Fracture & Fatigue For Bearing and Housing

Download Now

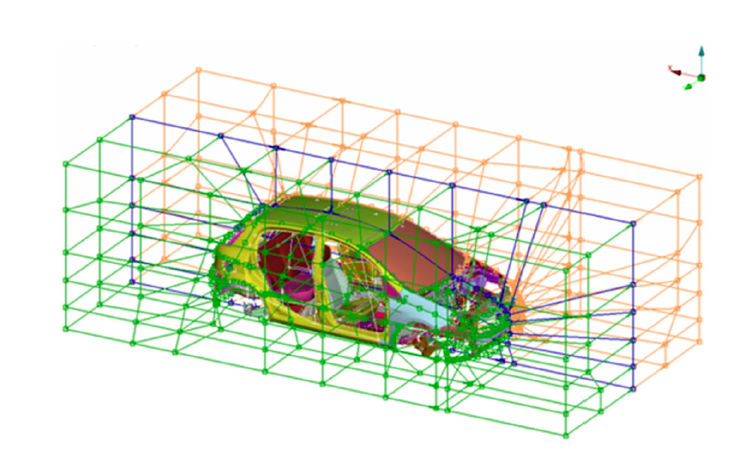

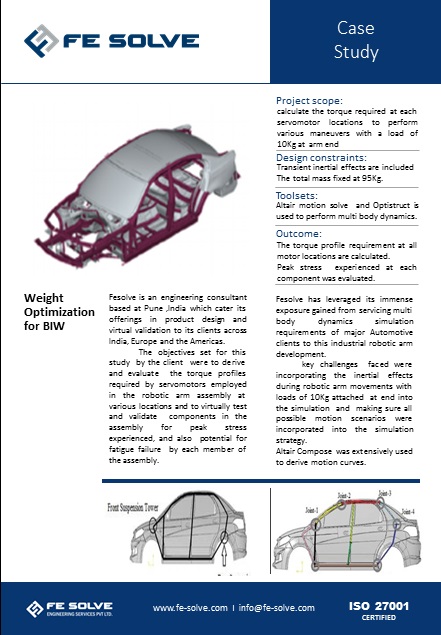

Optimization

FE S Solve caters optimization process which consists of minimal installation space or developments to a structure to lessen susceptibility to weak spots or remove them all collectively. We estimate possible optimization for a design utilizing various numerical procedures. When potential is uncovered, suggestions for upgrades to a component or an assembly group are incorporated into the development process. An offer for a whole new design can be achievable. Our technical engineers operate in close agreement with all sections through all phases of the growth procedure. The element design idea is taken into consideration together with material requirements, performance or boundary circumstances in the manufacturing process.

FE Solve specializes in:

- Topology optimization

- Topography optimization

- Parameter optimization

We specialize in the CAE optimization of the following industries of automobile field:

- Crash performance optimization is making use of a composite structure.

- Weld point optimization

- Reinforcement of local elements

- Bonding surface optimization

- Components in the powertrain

- Body components or general bodies

Weight optimization for BIW

Download NowStructural Optimization of Swing Arm

Download NowTorque Derivation Structural Optimization

Download Now

Mold Flow

FE Solve specialized in detecting the dynamic structural properties and utilize extensive NVH analyses to optimize all of them.Our technicians perform damped and un-damped vibration evaluation on various vibration techniques to ascertain dynamic structural properties. Energetic habits can indeed be analyzed, envisioned and enhanced depending on natural frequencies and organic reactions in a period and over a particular frequency span.For the vehicle industry, we have specialized on the following calculations in the area of dynamics :

General natural frequencies :

- Torsion

- Vertical bending

- Lateral Bending

- Front-end bending

- Rear parallelogram

- MAC factors

Modal analysis, local ( examples ) :

- Steering column

- Replacement wheel recess

- Doors, hatches, attached parts

- Roof cross associates

- Module cross associates

- MAC factors

Frequency reaction analysis

( examples ) :

- Frequency reactions to ease points

- Operational vibration methods

- Modal participation factors

- Local dynamic stiffness ( LDS )s

- Design of vibration absorbers

- Mirror shake

- Steering wheel shake

- Gear shift vibrations

We are also primarily focused on NVH for vehicle industry applications :

Mold Flow analysis for Instrument Panel

Download NowMold Flow analysis for Plastic component

Download Now

Fracture & Fatigue For Bearing and Housing

Download Now

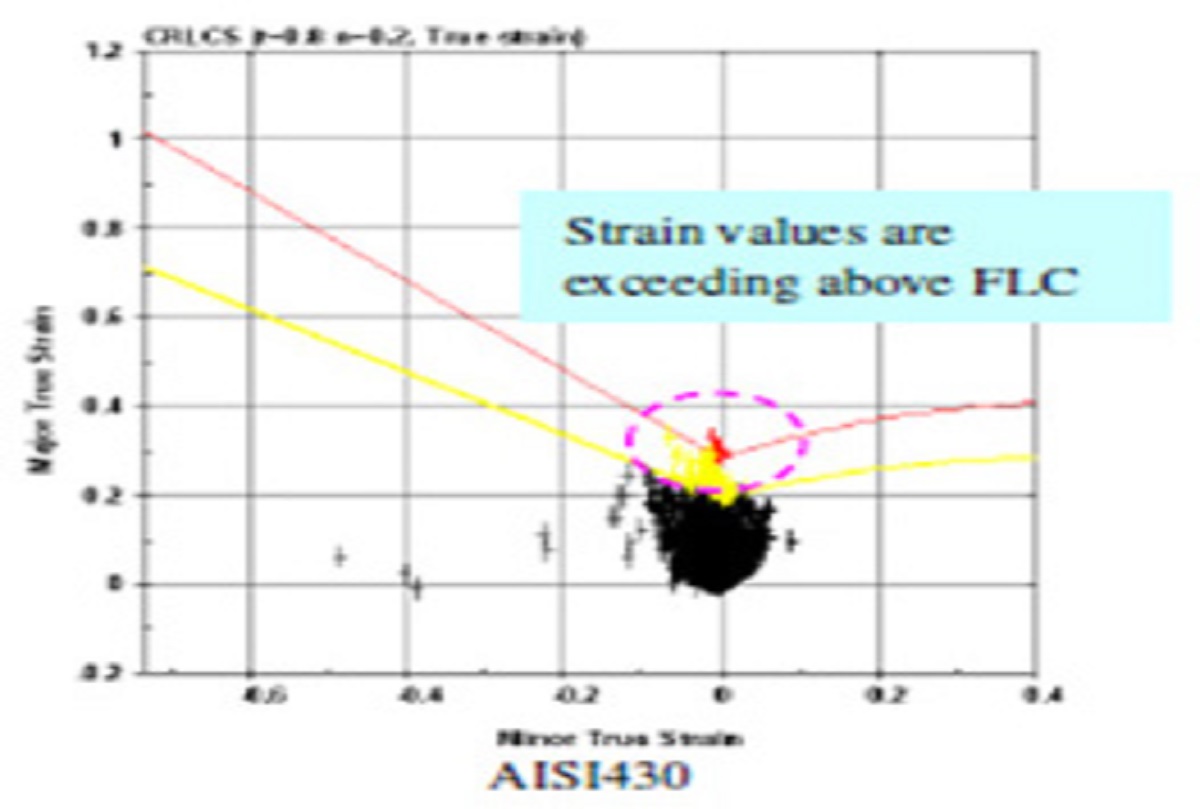

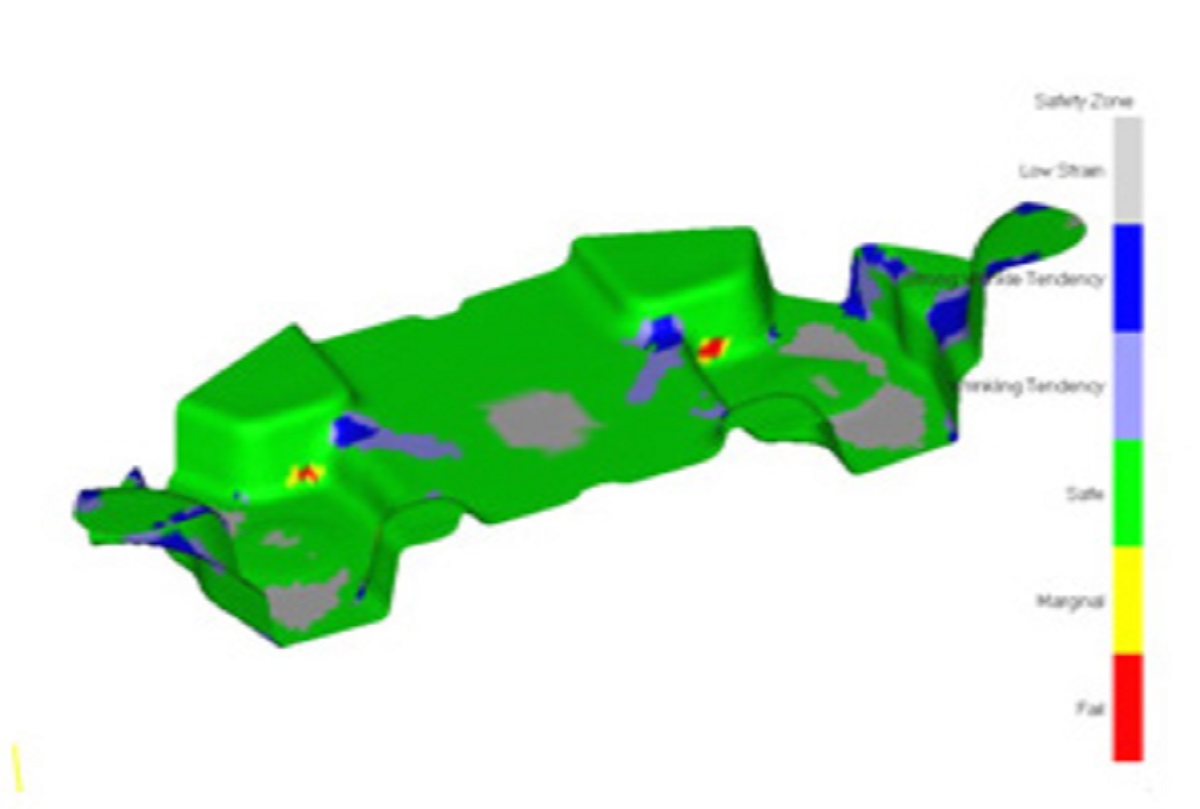

Sheet Metal Forming

FE Solve experienced in Tool Design, Simulation & Optimization and Manufacturing of Sheetmetal Components. We have the state-of-the art simulation capabilities and software to perform formability analysis, spring back verification, forming defect prediction, tool life estimation and process optimization.

- Sheet Forming Simulation

- Forming Limit Diagram(FLD)

- Formability Verification

- Defect Prediction – Crack, Splitting, Thinning, Wrinkling, Dent Resistance..

- Spring back Prediction

- Forming & Holding Force Prediction

- Contact Force Calculation & Contact Map

- Visualization

- Material Flow Evaluation

- Shock Line Evaluation

- Trim Line Evaluation

- Initial Blank Size Evaluation

- Fatigue Life Assessment

- Sheet metal Forming Parameter Optimization

Metal Forming Process

Download Now

Fracture & Fatigue For Bearing and Housing

Download Now

Fracture & Fatigue For Bearing and Housing

Download Now.png)